1- Thông số kỹ thuật:

- Spiral wound gasket có thể được là từ nhiều loại vật liệu khác nhau như: - Lá thép (hoop): Stainless steel (304, 316, 321, 347,…), titan, niken, hastelloy, đồng, nhôm,…

- Filler: Asbestos, PTFE, Expanded graphite, non asbestos,…

- Inner, Outering: Thép carbon, thép không rỉ (304, 316 410,…) monel, titan,….

Với nhiều loại tiêu chuẩn JIS, DIN, ANSI, BS, KS,…

+ Nhiệt độ làm việc ( max Working temperature ) : 800oC

- metal : ring joint

- non metal : cut gasket

Thường làm joint giữa 2 mặt bích

- metal sprial wound

GIOĂNG KIM LOẠI THÉP INOX CHỊU NHIỆT (SPIRAL WOUND GASKET) :

- Outer ring: carbon steel. Metal winding strip: 316L stainless steel. Filler material: standal purity graphite (SPG), Outer ring: SS316 & inner ring: SS316, SS304

- Outer ring: carbon steel. Inner ring: 316 stainless steel. Metal winding strip (Hoop): 316L stainless steel. Filler material: standal purity graphite (SPG)

- Spiral wound gaskets. Outer ring: 316 stainless steel. Inner ring: 316 stainless steel. Metal winding strip (Hoop): 316L stainless steel. Filler material: standal purity graphite (SPG)

- Spiral wound gaskets. Outer ring: 304 stainless steel. Inner ring: 304 stainless steel. Metal winding strip (Hoop): 316L stainless steel. Filler material: standal purity graphite (SPG)

- Outer ring: Vòng tròn phía ngoài cùng (có thể làm bằng carbon steel hay inox)

Inner ring: Vòng tròn phía trong cùng ( có thể làm bằng carbon steel hay inox)

Filler material: để làm kín 2 bề mặt kim loại

2 - Ứng Dụng

- Dùng làm kín các khớp nối trong đường ống, thiết bị trao đổi nhiệt, dùng để làm kín giữa 2 vật được nối bằng mặt bích

- Là loại gasket đa năng được dùng cho các ứng dụng chịu nhiệt, độ cao, môi trường nhiệt tuần hoàn, rung hoặc môi trường chân không cao trong các nghành luyện kim, dầu khí, hay hóa chất.

Gioăng đệm kim loại Spiral Wound Gasket phù hợp với môi trường có nhiệt độ và áp lực cao, môi trường oxi hóa mạnh trong hệ thống đường ống, bơm van công nghiệp, mặt bích. Flexitallic cung cấp đầy đủ các kích thước và chủng loại vòng đệm theo tiêu chuẩn hoặc theo yêu cầu khách hàng.

QT Engineering chuyên nhập khẩu và phân phối sản phẩm Gioăng đệm kim loại Spiral Wound Gasket Thermiculite 835 từ Flexitallic với chất lượng cao và giá cả cạnh tranh nhất thị trường Việt Nam.

Filler material: Thermiculite 835

Winding strip: Typical stainless 316L (Others available )

Centering/Compression ring(s): Typical stainless 316 (Others available)

| Maximum recommended temperature | 980ºC (1800ºF) |

| Maximum recommended pressure | ASME B16.5 2500lb, API 6FB Fire-Safe |

| Thickness range | 1.6 mm to 7.2 mm |

| Density | 1.2 ~ 1.3g/cm3 |

| ASTM Tensile Strength | 4.3Mpa |

| Leachable chloride ion content | < 50ppm |

| Leachable fluoride ion content | < 50ppm |

| Gasket size | Up to 3,000 mm |

| Class | 150 ~ 2500 |

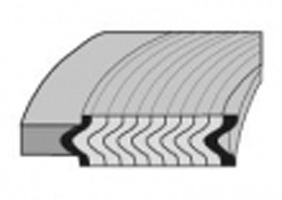

Style CG

Utilizes an external ring which accurately centers gasket on flange face: provides additional radial strength to prevent gasket blowout and acts as a compression stop. A general purpose gasket suitable for use with flat face and raised face flanges.

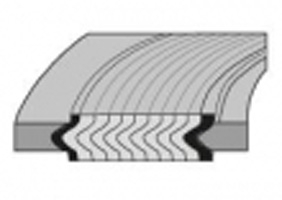

Style CGI

For use above class 600, this gasket is a Style CG gasket with an internal ring for an additional compression limiting stop. For use with flat face and raised face flanges, this gasket features increased compressive force for blow-out prevention and is specified for high pressure/temperature service or where corrosive or toxic media are present.

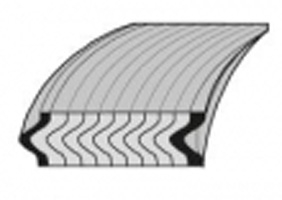

Style R & RIR

This spiral wound gasket is a sealing element only – controlled compression must be in the flange. Inner and outer diameters are reinforced with several plies of metal, without filler, to give greater stability and sealing. All other SWG’s (except Style R and HXRIR) have compression built into the gasket. We also offer Style R Spiral Wound Gasket which his fitted with an inner metal ring.

HF ALKYLATION

A Style CGI gasket developed further with metal reinforced graphite (MRG). The CGI-MRG has a metal core laminated with a conformable sealing material. The solid metal provides strength and rigidity also preventing blow-out. The soft facings give an exceptional seal at relatively low gasket stress. Face material and core thickness can be tailored to the application, and a wide range of core materials are available. Please contact us for more information.

The Baker Gasket offers the reliability of a spiral wound gasket with PTFE to prevent acid attacking bolts, plus an emissions containment system. Originally developed for refinery alkylation units, the Baker Gasket features and in-built early warning system for potential hydrofluoric leaks. Any HF acid leaking from the flange travels through an integrated channel in the gasket to the pan-handle which is coated in HF reactive paint – a highly visible indicator for potential leaks.

The gasket features an inner ring which can be manufactured in a variety of materials eg. Thermiculite® dependent on the media. Designed specifically for heat exchangers, the Style HX-RIR gasket is most commonly specified for shell and tube heat exchangers with a TEMA flange.

Low Stress

The style LS spiral wound gasket has been engineered by Flexitallic to provide an alternative to sheet gaskets in Class 150 and Class 300 service. Style LS gaskets have the inherent strength, resiliency and blowout resistance of spiral wound gaskets, yet require low bolt load for seating. They are manufactured with high purity Flexicarb flexible graphite filler or PTFE filler for optimum sealability, and are available for the full range of standard Class 150 and Class 300 flanges, as well as other non-standard low pressure flanges. The LSI features an additional inner ring for secure sealing and increased blow-out protection with high temperature and chemical resistance, therefore reducing maintenance costs.

Low Emission

The Flexitallic Low Emission gasket is a high performance spiral wound gasket that has been specially engineered to exceed stringent oil and gas industry fugitive emissions requirements, such as those found in the Chevron Fugitive Emissions Test (CFET). Independent testing in accordance with the CEFT protocol has show that Flexitallic Low Emission gaskets comfortable exceed allowable fugitive emission leakage levels. Leakage testing of ASME Class CGI spiral wound gaskets in accordance with the PVRC ROTT procedure shows that Flexitallic Low Emission gaskets require significantly lower bolt stress to achieve a T3 tightness class.

Spiral Wound Gasket Flexitallic Thermiculite 835 Datasheet

Style CG, CGI, R, RIR Datasheet

Quý khách vui lòng cung cấp thông tin khi yêu cầu gioăng đệm:

► Theo tiêu chuẩn: ANSI, JIS, DIN, BS,... hoặc phi tiêu chuẩn

► Loại vật liệu, kích thước, điều kiện môi trường sử dụng

Dây đồng bện , Thanh cái đồng mềm , Khớp nối nhanh inox , Dây đồng bện tiếp địa thang máng cáp , Ống mềm teflon bọc lưới inox 304 , Ống ruột gà inox 304 , Van bi tay gạt inox 304 , Thanh cái mềm ( Flexible busbar ) , Ống ruột gà lõi thép ,

Phone: 0932.210.082

Email: vuthaihcmute@gmail.com

Skype: thai_nguyenvu

Phone: 0979.647.727

Email: qtgasket@gmail.com

Skype: qt_gasket

CÔNG TY TNHH VẬT TƯ VÀ KỸ THUẬT QT

• Hotline : 0932.210.082 | 0979.647.727

• Email : vattukythuatqt@gmail.com

• Web : www.qtengineering.com